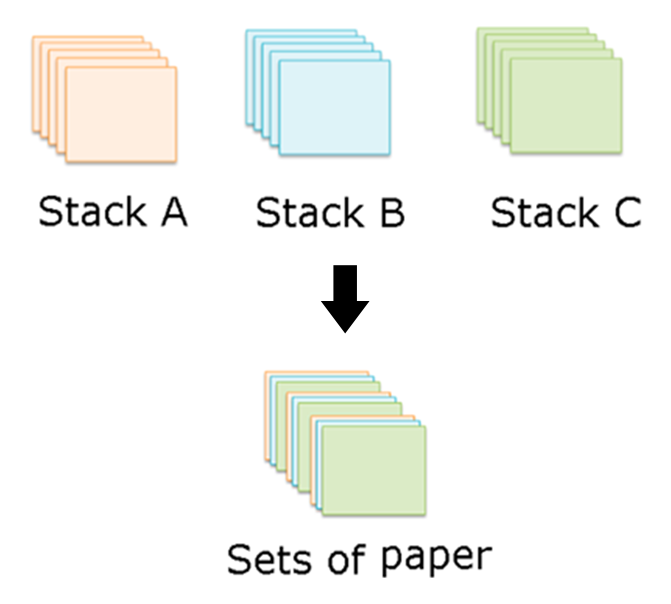

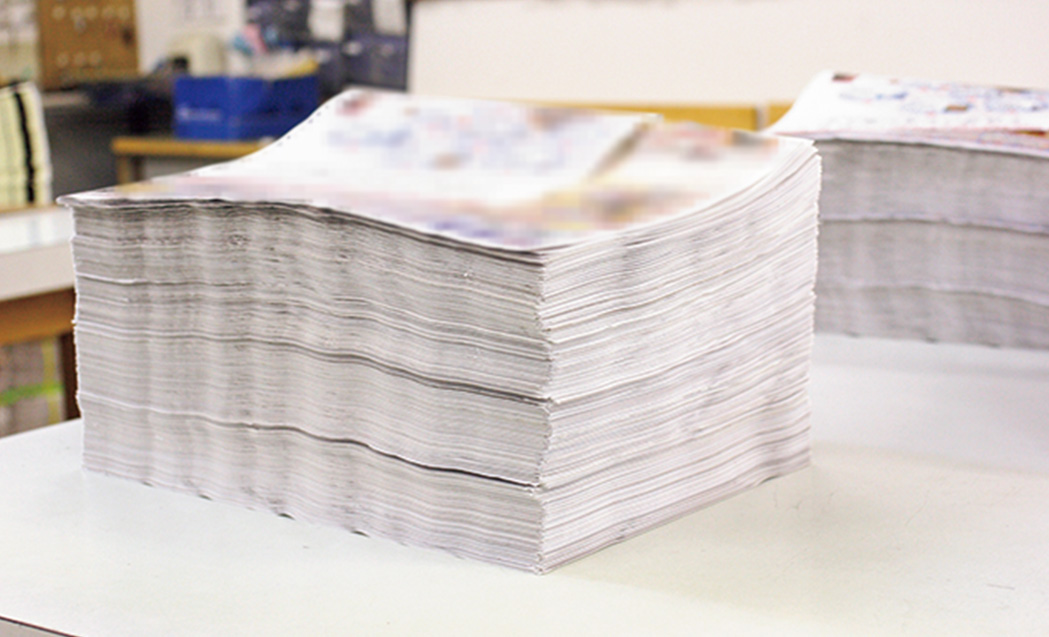

What is “Collating” and “Sorting”?

“Collating / sorting” refers to the process of picking sheets of paper from several different stacks of paper, and bundling them into a set. By using our machines, clients can dramatically shorten the time it takes, while improving accuracy, compared to manual work.